- N-channel MOSFET transistors (154) P-channel MOSFET transistors (25) Power blocks (21) Power stages (32) Multi-channel ICs (PMIC) (205) Offline & isolated DC/DC controllers & converters (585) Flyback controllers (50) Flybuck converters (15) Isolated DC/DC converters & modules (75) Load share controllers (6) Offline converters (4).

- P-MOSFET; Switch; Source Follower; Current Source; Current Ramp; Current Mirror; Common-Source Amplifier; CMOS Inverter; CMOS Inverter (w/capacitance) CMOS Inverter (slow transition) CMOS Transmission Gate; CMOS Multiplexer; Sample-and-Hold; Delayed Buffer; Leading-Edge Detector; Switchable Filter; Voltage Inverter; Inverter Amplifier; Inverter.

- Parasitic Capacitances: The schematic diagram of the MOSFET capacitances is shown in Figure below. Here, along with C g and C d, parasitic capacitances such as, junction capacitance between the source or drain diffusion and the substrate and overlap capacitance between the gate and the source or drain region are present. A) Junction capacitance (C j).

- An active-pixel sensor (APS) is an image sensor where each pixel sensor unit cell has a photodetector (typically a pinned photodiode) and one or more active transistors. In a metal–oxide–semiconductor (MOS) active-pixel sensor, MOS field-effect transistors (MOSFETs) are used as amplifiers.

Silicon carbide - The latest breakthrough in high-voltage switching and rectification. ST’s portfolio of silicon carbide devices incluses STPOWER SiC MOSFETs ranging from 650 to 1700 V with the industry’s highest junction temperature rating of 200 °C for more efficient and simplified designs, and STPOWER SiC diodes ranging from 600 to 1200 V which feature negligible switching losses.

The term CMOS stands for “Complementary Metal Oxide Semiconductor”. This is one of the most popular technology in the computer chip design industry and it is broadly used today to form integrated circuits in numerous and varied applications. Today’s computer memories, CPUs, and cell phones make use of this technology due to several key advantages. This technology makes use of both P channel and N channel semiconductor devices. One of the most popular MOSFET technologies available today is the Complementary MOS or CMOS technology. This is the dominant semiconductor technology for microprocessors, microcontroller chips, memories like RAM, ROM, EEPROM and application-specific integrated circuits (ASICs).

Introduction to MOS Technology

In the IC design, the basic and most essential component is the transistor. So MOSFET is one kind of transistor used in many applications. The formation of this transistor can be done like a sandwich by including a semiconductor layer, generally a wafer, a slice from a single crystal of silicon; a layer of silicon dioxide & a metal layer. These layers allow the transistors to be formed within the semiconductor material. A good insulator like Sio2 has a thin layer with a hundred molecules thickness.

The transistors which we use polycrystalline silicon (poly) instead of metal for their gate sections. The Polysilicon gate of FET can be replaced almost using metal gates in large scale ICs. Sometimes, both polysilicon & metal FET’s are referred to as IGFET’s which means insulated gate FETs, because the Sio2 below the gate is an insulator.

CMOS (Complementary Metal Oxide Semiconductor)

The main advantage of CMOS over NMOS and BIPOLAR technology is the much smaller power dissipation. Unlike NMOS or BIPOLAR circuits, a Complementary MOS circuit has almost no static power dissipation. Power is only dissipated in case the circuit actually switches. This allows integrating more CMOS gates on an IC than in NMOS or bipolar technology, resulting in much better performance. Complementary Metal Oxide Semiconductor transistor consists of P-channel MOS (PMOS) and N-channel MOS (NMOS). Please refer to the link to know more about the fabrication process of CMOS transistor.

NMOS

NMOS is built on a p-type substrate with n-type source and drain diffused on it. In NMOS, the majority of carriers are electrons. When a high voltage is applied to the gate, the NMOS will conduct. Similarly, when a low voltage is applied to the gate, NMOS will not conduct. NMOS is considered to be faster than PMOS, since the carriers in NMOS, which are electrons, travel twice as fast as the holes.

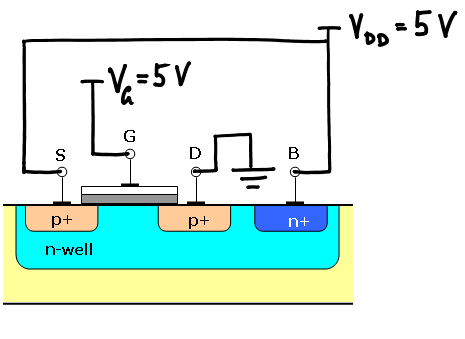

PMOS

P- channel MOSFET consists of P-type Source and Drain diffused on an N-type substrate. The majority of carriers are holes. When a high voltage is applied to the gate, the PMOS will not conduct. When a low voltage is applied to the gate, the PMOS will conduct. The PMOS devices are more immune to noise than NMOS devices.

Cmos Vs Mosfet

CMOS Working Principle

In CMOS technology, both N-type and P-type transistors are used to design logic functions. The same signal which turns ON a transistor of one type is used to turn OFF a transistor of the other type. This characteristic allows the design of logic devices using only simple switches, without the need for a pull-up resistor.

In CMOS logic gates a collection of n-type MOSFETs is arranged in a pull-down network between the output and the low voltage power supply rail (Vss or quite often ground). Instead of the load resistor of NMOS logic gates, CMOS logic gates have a collection of p-type MOSFETs in a pull-up network between the output and the higher-voltage rail (often named Vdd).

Thus, if both a p-type and n-type transistor have their gates connected to the same input, the p-type MOSFET will be ON when the n-type MOSFET is OFF, and vice-versa. The networks are arranged such that one is ON and the other OFF for any input pattern as shown in the figure below.

CMOS offers relatively high speed, low power dissipation, high noise margins in both states, and will operate over a wide range of source and input voltages (provided the source voltage is fixed). Furthermore, for a better understanding of the Complementary Metal Oxide Semiconductor working principle, we need to discuss in brief CMOS logic gates as explained below.

Which Devices use CMOS?

Technology like CMOS is used in different chips like microcontrollers, microprocessors, SRAM (static RAM) & other digital logic circuits. This technology is used in a wide range of analog circuits which includes data converters, image sensors & highly incorporated transceivers for several kinds of communication.

CMOS Inverter

The inverter circuit as shown in the figure below. It consists of PMOS and NMOS FET. The input A serves as the gate voltage for both transistors.

The NMOS transistor has input from Vss (ground) and the PMOS transistor has input from Vdd. The terminal Y is output. When a high voltage (~ Vdd) is given at input terminal (A) of the inverter, the PMOS becomes an open circuit, and NMOS switched OFF so the output will be pulled down to Vss.

When a low-level voltage (<Vdd, ~0v) applied to the inverter, the NMOS switched OFF and PMOS switched ON. So the output becomes Vdd or the circuit is pulled up to Vdd.

| INPUT | LOGIC INPUT | OUTPUT | LOGIC OUTPUT |

| 0 v | 0 | Vdd | 1 |

| Vdd | 1 | 0 v | 0 |

Cmos Mosfet How To Trigger

CMOS NAND Gate

The below figure shows a 2-input Complementary MOS NAND gate. It consists of two series NMOS transistors between Y and Ground and two parallel PMOS transistors between Y and VDD.

If either input A or B is logic 0, at least one of the NMOS transistors will be OFF, breaking the path from Y to Ground. But at least one of the pMOS transistors will be ON, creating a path from Y to VDD.

Hence, the output Y will be high. If both inputs are high, both of the nMOS transistors will be ON and both of the pMOS transistors will be OFF. Hence, the output will be logic low. The truth table of the NAND logic gate given in the below table.

| A | B | Pull-Down Network | Pull-up Network | OUTPUT Y |

| 0 | 0 | OFF | ON | 1 |

| 0 | 1 | OFF | ON | 1 |

| 1 | 0 | OFF | ON | 1 |

| 1 | 1 | ON | OFF | 0 |

CMOS NOR Gate

A 2-input NOR gate is shown in the figure below. The NMOS transistors are in parallel to pull the output low when either input is high. The PMOS transistors are in series to pull the output high when both inputs are low, as given in the below table. The output is never left floating.

The truth table of the NOR logic gate given in the below table.

| A | B | Y |

| 0 | 0 | 1 |

| 0 | 1 | 0 |

| 1 | 0 | 0 |

| 1 | 1 | 0 |

CMOS Fabrication

The fabrication of CMOS transistors can be done on the wafer of silicon. The diameter of the wafer ranges from 20mm to 300mm. In this, the Lithography process is the same as the printing press. On every step, different materials can be deposited, etched otherwise patterned. This process is very simple to understand by viewing the wafer’s top as well as cross-section within a simplified assembling method. The fabrication of CMOS can be accomplished through using three technologies namely N-well pt P-well, Twin well, an SOI (Silicon on Insulator). Please refer to this link to know more about CMOS Fabrication.

A Lifetime of CMOS Battery

The typical life span of a CMOS battery is approximately 10 Years. But, this can change based on the utilization and surroundings wherever the PC resides.

Failure Symptoms of CMOS Battery

When the CMOS battery fails, then the computer cannot maintain the exact time & date on the computer once it is switched off. For instance, once the computer is ON, you may see the time and date like 12:00 PM & January 1, 1990. This fault specifies that the battery of CMOS is failed.

- The boot-up of the laptop is difficult

- The beep sound can be generated continuously from the motherboard of the computer

- The time & date have reset

- Peripherals of the computers don’t respond correctly

- The drivers of hardware have vanished

- The Internet cannot be connected.

CMOS Characteristics

The most important characteristics of CMOS are low static power utilization, huge noise immunity. When the single transistor from the pair of MOSFET transistor is switched OFF then the series combination uses significant power throughout switching among the two stated like ON & OFF.

As a result, these devices do not generate waste heat as compared with other types of logic circuits such as TTL or NMOS logic, which usually use some standing current even they don’t change their state.

These CMOS characteristics will allow for integrating logic functions with high density on an integrated circuit. Because of this, CMOS has become the most frequently used technology to be executed within VLSI chips.

The phrase MOS is a reference to the MOSFET’s physical structure which includes an electrode with a metal gate that is located on the top of an oxide insulator of semiconductor material.

A material like Aluminum is used only once however the material is now polysilicon. The designing of other metal gates can be done using a comeback through the arrival of high-κ dielectric materials within the process of the CMOS process.

CCD Vs CMOS

The image sensors like the charge-coupled device (CCD) & complementary metal-oxide-semiconductor (CMOS) are two different kinds of technologies. These are used to capture the image digitally. Every image sensor has its advantages, disadvantages & applications.

The main difference between CCD & CMOS is the way of capturing the frame. A charge-coupled device like CCD uses a global shutter whereas the CMOS uses a rolling shutter. These two image sensors change the charge from light to electrical & process it into electronic signals.

The manufacturing process used in CCDs is special to form the capacity to move charge across the IC without alteration. So, this manufacturing process can lead to extremely high-quality sensors about light sensitivity & fidelity.

In contrast, CMOS chips use fixed manufacturing procedures to design the chip and a similar process can also be used in making the microprocessors. Because of the differences in manufacturing, there are some clear dissimilarities among the sensors like CCD 7 CMOS.

CCD sensors will capture the images with less noise and huge quality whereas the CMOS sensors are usually more liable to noise.

Usually, CMOS uses less power whereas the CCD uses lots of power like more than 100 times to CMOS sensor.

The fabrication of CMOS chips can be done on any typical Si production line because they tend to be very cheap as compared with CCDs. CCD sensors are more mature because they are mass-produced for a long period.

Both the CMOS & CCD imagers depend on the effect of photoelectric to make the electrical signal from the light

Based on the above differences, CCDs are used in cameras to target high-quality images through lots of pixels & outstanding light sensitivity. Usually, CMOS sensors have less resolution, quality & sensitivity.

In some applications, CMOS sensors are recently improving to the point wherever they attain near equality with CCD devices. Generally, CMOS cameras are not expensive & they have a high life of the battery.

Latch-Up in CMOS

A latch-up can be defined as when the short circuit occurs between the two terminals like power and ground so that high current can be generated & IC can be damaged. In CMOS, latch-up is the occurrence of low impedance trail among the power rail & ground rail because of the communication between the two transistors like parasitic PNP & NPN transistors.

In the CMOS circuit, the two transistors like PNP & NPN is connected to two supply rails like VDD & GND. The protection of these transistors can be done through resistors.

In a latch-up transmission, the current will flow from VDD to GND straight through the two transistors so that a short circuit can occur, thus extreme current will flow from VDD to the ground terminal.

There are different methods for latch-up prevention

In latch-up prevention, high resistance can be placed in the trail to stop the flow of current throughout supply & to make β1 *β2 below 1 by using the following methods.

The structure of parasitic SCR will be beaked in the surrounding of transistors like PMOS & NMOS through an insulating oxide layer. The technology for latch-up protection will turn off the device once latch-up is noticed.

The testing services of latch-up can be done by many vendors in the market. This test can be done by a sequence of attempts to activate the structure of SCR in the CMOS IC whereas the related pins are checked when overcurrent flows through it.

It is advised to obtain the first samples from the experimental lot & send them to a testing lab of Latch-up. This lab will apply the utmost achievable power supply & then provide the current supply to the inputs & outputs of the chip whenever a Latch-up occurs through monitoring the current supply.

Advantages

The advantages of CMOS include the following.

The main benefits of CMOS over TTL are good noise margin as well as less power consumption. This is due to no straight conducting lane from VDD to GND, fall times based on the conditions of input, then the transmission of the digital signal will become easy & low cost through CMOS chips.

CMOS is used to explain the amount of memory on the motherboard of the computer that will store in the settings of BIOS. These settings mainly include the date, time, and settings of hardware

TTL is a digital logic circuit where bipolar transistors work on DC pulses. Several transistor logic gates are normally made-up of a single IC.

The outputs if CMOS drive actively in both ways

- It uses a single power supply like + VDD

- These gates are very simple

- Input impedance is high

- CMOS logic uses less power whenever it is held in a set state

- Power dissipation is negligible

- Fan out is high

- TTL compatibility

- Stability of temperature

- Noise immunity is good

- Compact

- Designing is very well

- Robust mechanically

- Logic swing is large (VDD)

Disadvantages

The disadvantages of CMOS include the following.

- The cost will be increased once the processing steps increases, however, it can be resolved.

- The packing density of CMOS is low as compared with NMOS.

- MOS chips should be secured from getting static charges by placing the leads shorted otherwise; the static charges obtained within leads will damage the chip. This problem can be solved by including protective circuits otherwise devices.

- Another drawback of the CMOS inverter is that it utilizes two transistors as opposed to one NMOS to build an inverter, which means that the CMOS uses more space over the chip as compared with the NMOS. These drawbacks are small due to the progress within the CMOS technology.

CMOS Applications

Complementary MOS processes were widely implemented and have fundamentally replaced NMOS and bipolar processes for nearly all digital logic applications. CMOS technology has been used for the following digital IC designs.

- Computer memories, CPUs

- Microprocessor designs

- Flash memory chip designing

- Used to design application-specific integrated circuits (ASICs)

Thus, the CMOS transistor is very famous because they use electrical power efficiently. They don’t use electrical supply whenever they are altering from one condition to another. Also, the complimentary semiconductors work mutually to stop the o/p voltage. The outcome is a low-power design that provides less heat, due to this reason, these transistors have changed other earlier designs like CCDs within camera sensors & utilized in most of the current processors. The memory of the CMOS within a computer is a kind of non-volatile RAM that store BIOS settings & the information of time and date.

I believe that you have got a better understanding of this concept. Furthermore, any queries regarding this concept or electronics projects, please give your valuable suggestions by commenting in the comment section below. Here is a question for you, why CMOS is preferable to NMOS?

The threshold voltage, commonly abbreviated as Vth, of a field-effect transistor (FET) is the minimum gate-to-source voltage VGS (th) that is needed to create a conducting path between the source and drain terminals. It is an important scaling factor to maintain power efficiency.

When referring to a junction field-effect transistor (JFET), the threshold voltage is often called pinch-off voltage instead.[1][2] This is somewhat confusing since pinch off applied to insulated-gate field-effect transistor (IGFET) refers to the channel pinching that leads to current saturation behaviour under high source–drain bias, even though the current is never off. Unlike pinch off, the term threshold voltage is unambiguous and refers to the same concept in any field-effect transistor.

Basic principles[edit]

In n-channelenhancement-mode devices, a conductive channel does not exist naturally within the transistor, and a positive gate-to-source voltage is necessary to create one such. The positive voltage attracts free-floating electrons within the body towards the gate, forming a conductive channel. But first, enough electrons must be attracted near the gate to counter the dopant ions added to the body of the FET; this forms a region with no mobile carriers called a depletion region, and the voltage at which this occurs is the threshold voltage of the FET. Further gate-to-source voltage increase will attract even more electrons towards the gate which are able to create a conductive channel from source to drain; this process is called inversion. The reverse is true for the p-channel 'enhancement-mode' MOS transistor. When VGS = 0 the device is “OFF” and the channel is open / non-conducting. The application of a negative (-ve) gate voltage to the p-type 'enhancement-mode' MOSFET enhances the channels conductivity turning it “ON”.

In contrast, n-channel depletion-mode devices have a conductive channel naturally existing within the transistor. Accordingly, the term threshold voltage does not readily apply to turning such devices on, but is used instead to denote the voltage level at which the channel is wide enough to allow electrons to flow easily. This ease-of-flow threshold also applies to p-channeldepletion-mode devices, in which a negative voltage from gate to body/source creates a depletion layer by forcing the positively charged holes away from the gate-insulator/semiconductor interface, leaving exposed a carrier-free region of immobile, negatively charged acceptor ions.

For the n-channel depletion MOS transistor, a negative gate-source voltage, -VGS will deplete (hence its name) the conductive channel of its free electrons switching the transistor “OFF”. Likewise for a p-channel 'depletion-mode' MOS transistor a positive gate-source voltage, +VGS will deplete the channel of its free holes turning it “OFF”.

In wide planar transistors the threshold voltage is essentially independent of the drain–source voltage and is therefore a well defined characteristic, however it is less clear in modern nanometer-sized MOSFETs due to drain-induced barrier lowering.

In the figures, the source (left side) and drain (right side) are labeled n+ to indicate heavily doped (blue) n-regions. The depletion layer dopant is labeled NA− to indicate that the ions in the (pink) depletion layer are negatively charged and there are very few holes. In the (red) bulk the number of holes p = NA making the bulk charge neutral.

If the gate voltage is below the threshold voltage (left figure), the 'enhancement-mode' transistor is turned off and ideally there is no current from the drain to the source of the transistor. In fact, there is a current even for gate biases below the threshold (subthreshold leakage) current, although it is small and varies exponentially with gate bias.

If the gate voltage is above the threshold voltage (right figure), the 'enhancement-mode' transistor is turned on, due to there being many electrons in the channel at the oxide-silicon interface, creating a low-resistance channel where charge can flow from drain to source. For voltages significantly above the threshold, this situation is called strong inversion. The channel is tapered when VD > 0 because the voltage drop due to the current in the resistive channel reduces the oxide field supporting the channel as the drain is approached.

Body effect[edit]

The body effect is the change in the threshold voltage by an amount approximately equal to the change in the source-bulk voltage, , because the body influences the threshold voltage (when it is not tied to the source). It can be thought of as a second gate, and is sometimes referred to as the back gate,and accordingly the body effect is sometimes called the back-gate effect.[3]

For an enhancement-mode nMOS MOSFET, the body effect upon threshold voltage is computed according to the Shichman–Hodges model,[4] which is accurate for older process nodes,[clarification needed] using the following equation:

where is the threshold voltage when substrate bias is present, is the source-to-body substrate bias, is the surface potential, and is threshold voltage for zero substrate bias, is the body effect parameter, is oxide thickness, is oxide permittivity, is the permittivity of silicon, is a doping concentration, is elementary charge.

Dependence on oxide thickness[edit]

In a given technology node, such as the 90-nm CMOS process, the threshold voltage depends on the choice of oxide and on oxide thickness. Using the body formulas above, is directly proportional to , and , which is the parameter for oxide thickness.

Thus, the thinner the oxide thickness, the lower the threshold voltage. Although this may seem to be an improvement, it is not without cost; because the thinner the oxide thickness, the higher the subthreshold leakage current through the device will be. Consequently, the design specification for 90-nm gate-oxide thickness was set at 1 nm to control the leakage current.[5] This kind of tunneling, called Fowler-Nordheim Tunneling.[6]

where and are constants and is the electric field across the gate oxide.

Before scaling the design features down to 90 nm, a dual-oxide approach for creating the oxide thickness was a common solution to this issue. With a 90 nm process technology, a triple-oxide approach has been adopted in some cases.[7] One standard thin oxide is used for most transistors, another for I/O driver cells, and a third for memory-and-pass transistor cells. These differences are based purely on the characteristics of oxide thickness on threshold voltage of CMOS technologies.

Temperature dependence[edit]

Cmos Mosfet Unterschied

As with the case of oxide thickness affecting threshold voltage, temperature has an effect on the threshold voltage of a CMOS device. Expanding on part of the equation in the body effect section

where is half the contact potential, is Boltzmann's constant, is temperature, is the elementary charge, is a doping parameter and is the intrinsic doping parameter for the substrate.

We see that the surface potential has a direct relationship with the temperature. Looking above, that the threshold voltage does not have a direct relationship but is not independent of the effects. This variation is typically between −4 mV/K and −2 mV/K depending on doping level.[8] For a change of 30 °C this results in significant variation from the 500 mV design parameter commonly used for the 90-nm technology node.

Dependence on random dopant fluctuation[edit]

Random dopant fluctuation (RDF) is a form of process variation resulting from variation in the implanted impurity concentration. In MOSFET transistors, RDF in the channel region can alter the transistor's properties, especially threshold voltage. In newer process technologies RDF has a larger effect because the total number of dopants is fewer.[9]

Research works are being carried out in order to suppress the dopant fluctuation which leads to the variation of threshold voltage between devices undergoing same manufacturing process.[10]

See also[edit]

Mosfet Cmos Logic

References[edit]

- ^'Junction Field Effect Transistor (JFET)'(PDF). ETEE3212 Lecture Notes.

This is called the threshold, or pinch-off, voltage and occurs at vGS=VGS(OFF).

- ^Sedra, Adel S.; Smith, Kenneth C. '5.11 THE JUNCTION FIELD-EFFECT TRANSISTOR (JFET)'(PDF). Microelectronic Circuits.

For JFETs the threshold voltage is called the pinch-off voltage and is denoted VP.

- ^Marco Delaurenti, PhD dissertation, Design and optimization techniques of high-speed VLSI circuits (1999))Archived 2014-11-10 at the Wayback Machine

- ^NanoDotTek Report NDT14-08-2007, 12 August 2007

- ^Sugii, Watanabe and Sugatani. Transistor Design for 90-nm Generation and Beyond. (2002)

- ^S. M. Sze, Physics of Semiconductor Devices, Second Edition, New York: Wiley and Sons, 1981, pp. 496–504.

- ^Anil Telikepalli, Xilinx Inc, Power considerations in designing with 90 nm FPGAs (2005))[1]

- ^Weste and Eshraghian, Principles of CMOS VLSI Design : a systems perspective, Second Edition, (1993) pp.48 ISBN0-201-53376-6

- ^Asenov, A. Huang,Random dopant induced threshold voltage lowering and fluctuations in sub-0.1 μm MOSFET's: A 3-D “atomistic” simulation study, Electron Devices, IEEE Transactions, 45 , Issue: 12

- ^Asenov, A. Huang,Suppression of random dopant-induced threshold voltage fluctuations in sub-0.1-μm MOSFET's with epitaxial and δ-doped channels, Electron Devices, IEEE Transactions, 46, Issue: 8

How Does A Mosfet Work

External links[edit]

- Online lecture on: Threshold Voltage and MOSFET Capacitances by Dr. Lundstrom